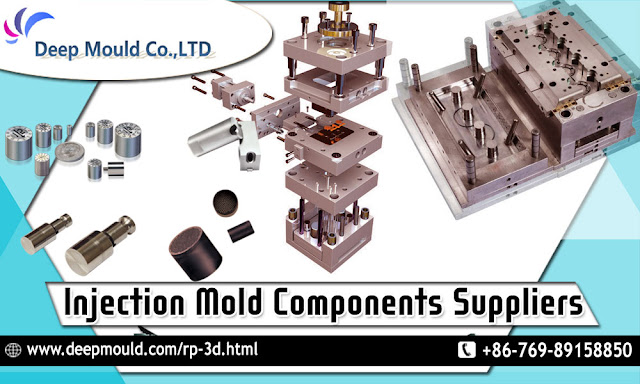

All About Injection Mold Components Suppliers

Injection molding is a molding strategy whereby warmth mollified plastic materials is forced from a chamber into a generally cool pit giving the article the coveted shape . Injection molding is a fabricating a gadget for making parts from plastic substances . Liquid plastic is infused at high weight into a mold, which is backward of the coveted shape. The plastic injection molding is made by a mold creator from metal, as a rule, either steel or aluminum, and accuracy machined to form the highlights of the coveted part. Injection molding is broadly utilized for assembling an assortment of parts, from the littlest segment to whole body panels of cars. Advantages of Injection Molding 1. High resilience are repeatable 2. Extensive variety of materials can be utilized 3. Low work costs 4. Negligible piece misfortunes 5. Little need to complete parts subsequent to molding Overview Injection molding is a moderately better approach to produce parts. It is a fast p